What are the branches of quantitative management? This question is essential for managers, business students, and professionals in a world where data-driven decision-making defines success.

Quantitative management is a structured approach that applies mathematical models, statistics, and data analysis to guide business strategies and operations.

This method emerged during World War II, when military planners developed techniques to optimize resources and improve outcomes. After the war, businesses adopted these practices to enhance production efficiency, manage resources, and reduce costs.

In today’s digital economy, knowing the branches of quantitative management helps professionals understand how different tools and methods work together to solve complex business challenges. This guide explores each branch, key tools, practical examples, and the benefits and limitations of applying quantitative methods in 2025.

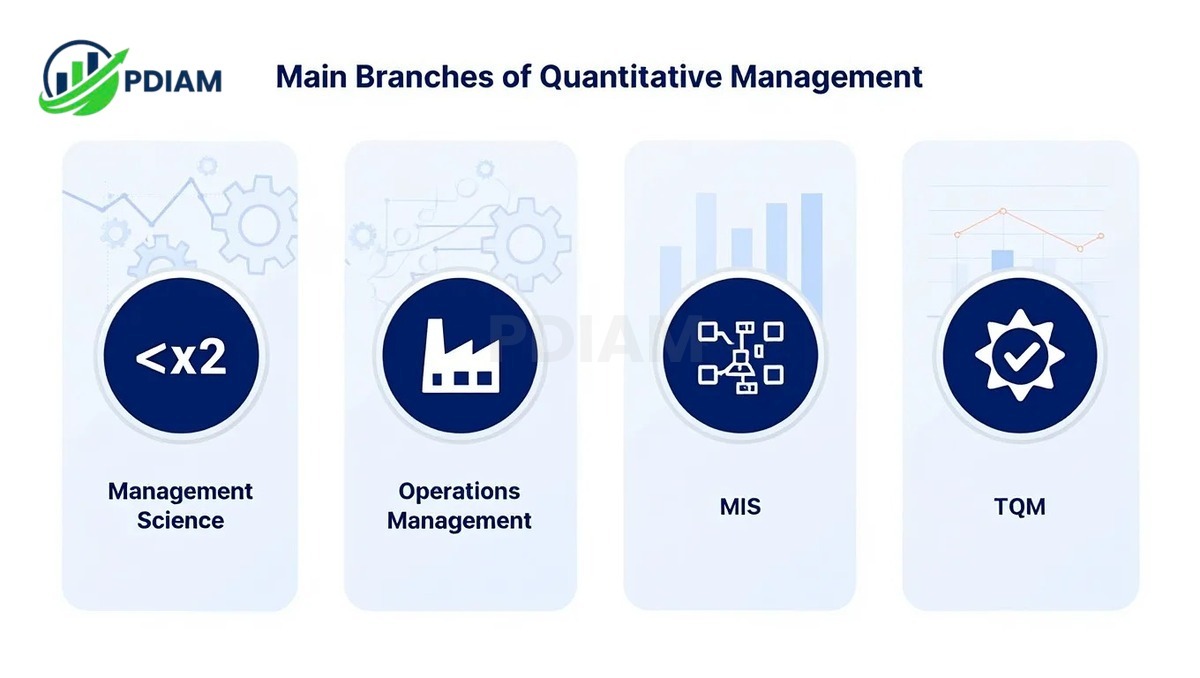

1. The main branches of quantitative management

Quantitative management is divided into several core branches, each focusing on specific business functions and decision-making areas.

-

Management Science (Operations Research) – Uses mathematical modeling to solve complex problems and optimize the use of resources.

-

Operations Management – Applies quantitative techniques to streamline production processes, improve quality, and manage supply chains.

-

Management Information Systems (MIS) – Collects, processes, and analyzes data to support decision-making at all management levels.

-

Total Quality Management (TQM) – Uses statistical tools to continuously improve product and service quality.

These branches often overlap, and many organizations integrate multiple branches to create a comprehensive decision-making framework.

Table: Summary of the main branches of quantitative management

| Branch | Core Focus | Common Methods | Application Areas |

|---|---|---|---|

| Management Science | Decision optimization | Linear programming, simulation | Strategic planning, resource allocation |

| Operations Management | Process efficiency | Inventory models, scheduling | Manufacturing, logistics |

| Management Information Systems | Data-driven decisions | DSS, TPS, EIS | Retail, performance monitoring |

| Total Quality Management | Continuous improvement | SPC, Six Sigma | Manufacturing, service quality |

Understanding these distinctions allows managers to select the right branch—or combination of branches—for specific challenges.

2. Management Science (Operations Research)

Management Science, also known as Operations Research, uses mathematical models to aid decision-making in resource allocation, logistics, and process optimization.

Key methods

-

Linear programming – Maximizes or minimizes an objective (e.g., cost, profit) subject to constraints.

-

Simulation – Tests different operational scenarios through computer models before implementation.

-

Queuing theory – Analyzes waiting times and service efficiency in systems like call centers and airports.

Real example: Airlines use management science to optimize flight schedules and routes, reducing fuel consumption while improving customer satisfaction.

By applying these methods, businesses can confidently tackle resource and scheduling challenges.

3. Operations Management

Operations Management is the discipline of overseeing, designing, and controlling production processes to ensure that goods and services are produced efficiently, on time, and to the required quality standards.

By applying quantitative techniques, operations managers can streamline workflows, reduce waste, and maintain consistent product or service quality.

Key techniques

-

Inventory models – Analytical methods that help businesses determine optimal stock levels, preventing both overstocking (which ties up capital) and stockouts (which risk lost sales). Common models include Economic Order Quantity (EOQ) and Just-in-Time (JIT) systems.

-

Forecasting – Uses historical data and statistical methods to predict customer demand, enabling better planning for production, staffing, and resource allocation. Forecasting can be short-term for daily operations or long-term for strategic planning.

-

Production scheduling – Allocates tasks, machinery, and labor in the most efficient way possible, reducing downtime and ensuring production targets are met. Advanced scheduling techniques can incorporate constraints like machine capacity and labor shifts.

Pro tip: Always integrate forecasting with real-time sales and operational data to adjust production and supply chain plans dynamically, reducing both waste and missed opportunities.

When implemented effectively, operations management connects mathematical analysis with daily operational execution, ensuring that businesses remain competitive, responsive, and cost-efficient.

View more:

- 2025’s Ten top Billionaires in the World ranked

- Which country markets are highest growing market in the world? (2025 Guide)

- Is the Bank of Dave a True Story? The complete impact revealed in 2025

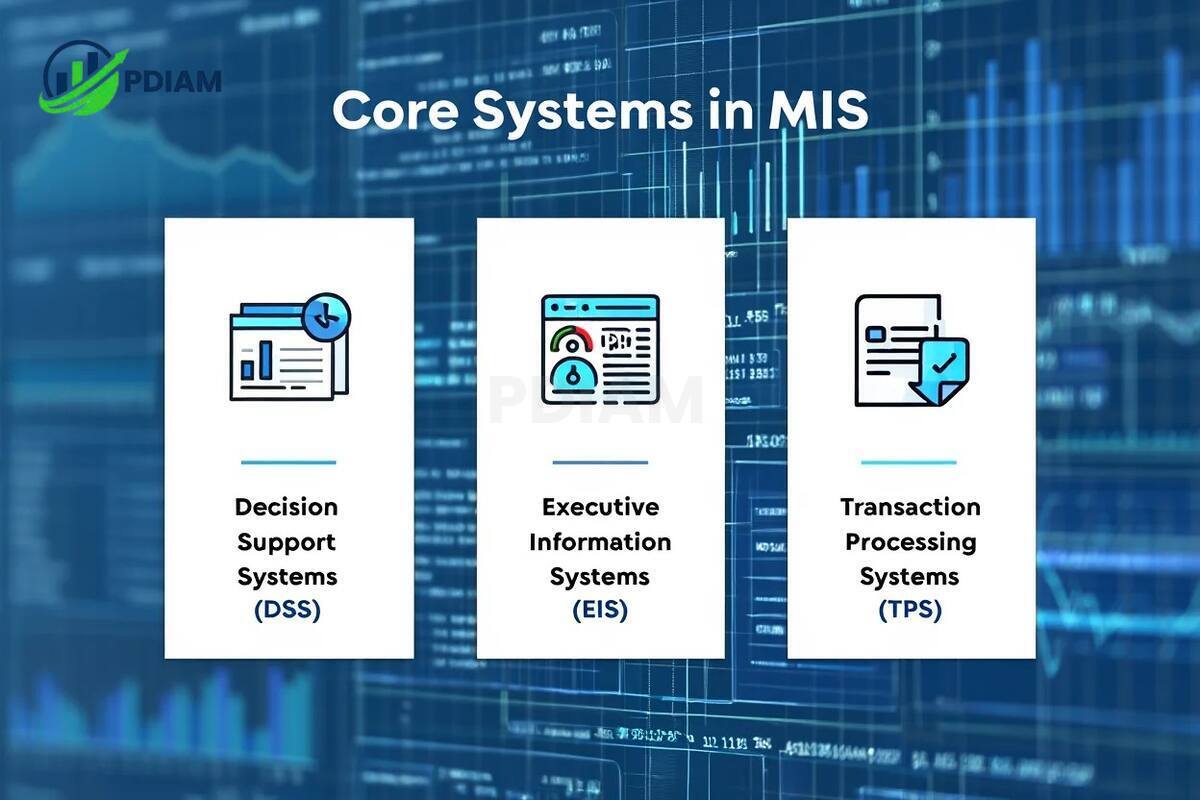

4. Management Information Systems (MIS)

Management Information Systems (MIS) integrate technology, people, and organizational processes to transform raw data into meaningful, actionable insights. They play a crucial role in helping managers at all levels make informed decisions by providing timely, accurate, and relevant information.

Within Management Information Systems (MIS), there are several core subsystems that support different levels of decision-making and operational control. Each plays a distinct role in transforming raw data into actionable business intelligence.

-

Decision Support Systems (DSS) – Analytical tools that process large amounts of data to model different scenarios, evaluate options, and recommend solutions. DSS allows managers to test “what-if” situations before committing to a course of action.

-

Executive Information Systems (EIS) – High-level platforms designed for senior management, offering performance dashboards, strategic indicators, and real-time KPIs. EIS ensures leaders have a clear overview of business health and can spot trends early.

-

Transaction Processing Systems (TPS) – Systems that handle day-to-day operational transactions such as sales, payroll, and inventory updates. TPS ensures data accuracy and consistency, forming the foundation for higher-level analysis.

Real example: Large retail chains use MIS to combine historical sales data with predictive analytics, enabling accurate sales forecasts and efficient inventory management. This integration not only improves stock availability but also enhances customer satisfaction.

By connecting operational data with strategic decision-making, MIS bridges the gap between raw information and impactful business actions.

5. Total Quality Management (TQM)

Total Quality Management (TQM) is a management philosophy that focuses on continuous improvement across all functions of an organization, with a strong reliance on statistical tools and data-driven evaluation.

It integrates quality into every stage of operations, aiming to enhance customer satisfaction and organizational performance over the long term.

Key techniques

-

Statistical Process Control (SPC) – A method for monitoring, controlling, and improving production processes by analyzing data from various stages of production. SPC helps identify deviations from quality standards early, enabling corrective actions before defects occur.

-

Six Sigma – A structured approach that uses statistical methods to reduce variation and eliminate defects in processes. Six Sigma projects follow the DMAIC (Define, Measure, Analyze, Improve, Control) framework to systematically improve performance and achieve near-perfect quality levels.

TQM also emphasizes employee involvement, encouraging all staff to contribute ideas for quality enhancement, and customer focus, ensuring that improvements align with client needs and expectations.

This combination of quantitative analysis, cultural commitment, and strategic alignment has made TQM especially effective in both manufacturing and service industries aiming for operational excellence.

6. Core tools across branches

Several tools are applied across multiple branches:

-

Linear programming – Management Science, Operations Management

-

Queuing theory – Management Science, Operations Management

-

Simulation – Management Science, MIS

-

Statistical quality control – TQM, Operations Management

-

Regression analysis – MIS, Management Science

-

Time-series analysis – Operations Management, MIS

-

Break-even analysis – Management Science, MIS

-

Decision trees – Management Science

-

PERT/CPM – Operations Management

-

Game theory – Management Science

-

Forecasting – Operations Management, MIS

Mastering these tools equips managers to address a wide range of business problems effectively.

View more:

- Sample letter of termination of appointment: Free template [2025]

- Best grants for women to start a business: Top 2025 list

- What is gap medical insurance coverage? Must-know facts

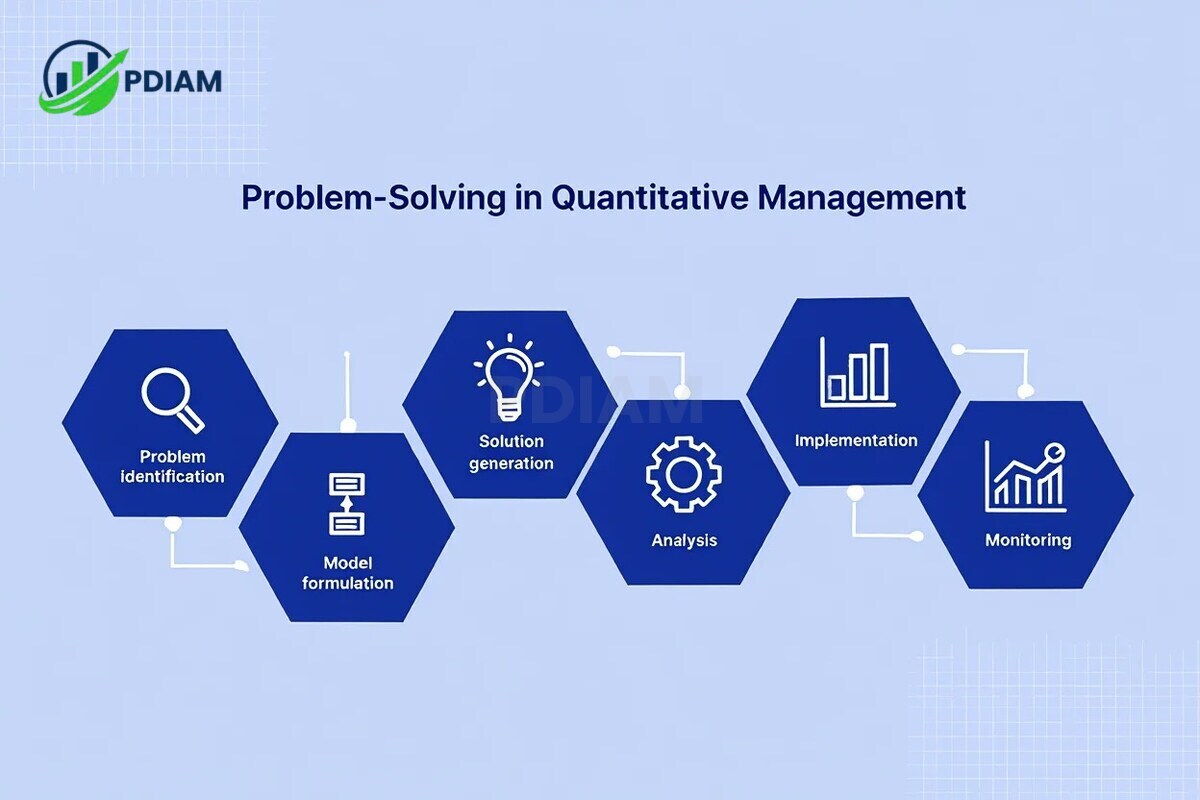

7. Problem-solving process in quantitative management

Quantitative management uses a structured approach:

-

Problem identification – Define the issue clearly.

-

Model formulation – Create a mathematical or logical model.

-

Solution generation – Apply quantitative methods to generate options.

-

Analysis – Evaluate solutions for feasibility and impact.

-

Implementation – Put the chosen solution into practice.

-

Monitoring – Track results and make adjustments.

This ensures systematic, data-driven decision-making.

8. Assumptions and principles

For quantitative management to be effective, it operates on several core assumptions and guiding principles. These assumptions shape the way models are built, data is interpreted, and decisions are made.

-

Organizations act as rational decision systems – The approach assumes businesses make logical, goal-oriented choices based on available information.

-

Key factors are measurable and analyzable – Success relies on the ability to quantify relevant variables, from production rates to market trends.

-

Data-driven decisions are superior to intuition – Objective analysis is prioritized over gut feelings, ensuring consistency and repeatability in decisions.

-

Collaboration across disciplines improves results – Bringing together experts in mathematics, IT, operations, and business ensures more robust solutions.

These principles ensure that quantitative management methods remain relevant, precise, and effective when applied in real-world business environments.

9. Benefits of applying quantitative management

Applying quantitative management techniques offers a wide range of strategic and operational advantages. By relying on data and analytical models, organizations can enhance performance across multiple dimensions.

-

Improves decision accuracy – Reduces guesswork by basing choices on verified data and mathematical models.

-

Allocates resources efficiently – Ensures that manpower, materials, and capital are used where they deliver the most value.

-

Optimizes processes for higher quality output – Streamlines workflows to improve consistency and reduce waste.

-

Enhances predictability and risk control – Models help anticipate potential challenges and design proactive solutions.

-

Supports detailed planning and forecasting – Facilitates accurate projections for budgets, demand, and capacity planning.

-

Promotes objectivity and consistency – Establishes standard procedures for evaluating options and outcomes.

-

Enables faster responses to market changes – Real-time data allows for quick adjustments in strategy or operations.

-

Offers competitive strategic advantages – Data-driven insights reveal opportunities competitors may miss.

-

Improves problem-solving frameworks – Encourages structured approaches that address root causes, not just symptoms.

-

Strengthens quality control – Integrates statistical tools to monitor and maintain high-quality standards.

-

Encourages transparency and accountability – Provides measurable criteria for evaluating performance.

-

Supports digital transformation – Aligns with technologies like AI, IoT, and automation to drive innovation.

-

Drives sustainable performance improvements – Creates long-term efficiencies that compound over time.

When implemented effectively, these benefits position quantitative management as a key driver of operational excellence and strategic growth.

10. Limitations and challenges

While the benefits of quantitative management are substantial, it is important to acknowledge its limitations and potential challenges. Understanding these issues helps organizations prepare realistic expectations and create effective mitigation strategies.

-

Requires high-quality, complete data – Inaccurate or incomplete data can lead to misleading conclusions and flawed decisions.

-

Models can be complex and difficult to interpret – Without proper training, stakeholders may misinterpret results.

-

May rely on unrealistic assumptions – Some models oversimplify real-world conditions, which can reduce accuracy.

-

Implementation and adoption can be challenging – Change management is often required to integrate new systems into existing workflows.

-

Training and system costs are high – Specialized software, hardware, and skilled personnel can be expensive to acquire and maintain.

-

May overlook qualitative factors – Human behavior, culture, and intuition are often underrepresented in purely quantitative approaches.

-

Models can be inflexible in unusual situations – Sudden market disruptions or atypical conditions may fall outside the model’s scope.

-

Computational limits may exist – Extremely large datasets or complex models can strain computing resources.

-

Communication gaps between technical and non-technical staff – Misalignment in understanding can slow decision-making.

-

Results depend heavily on analyst skill – Poorly applied methods can lead to incorrect or biased conclusions.

-

Potential ethical blind spots in modeling – Certain models may inadvertently reinforce biases or lead to unfair outcomes.

Recognizing these challenges allows organizations to apply quantitative management more responsibly, balancing the precision of data with the flexibility of human judgment.

11. Quantitative management in 2025

In 2025, quantitative management has evolved to integrate seamlessly with artificial intelligence (AI), Big Data, and broader digital transformation initiatives. These advancements have enhanced not only the volume of data collected but also the speed, accuracy, and sophistication of analyses.

AI-powered algorithms now allow organizations to process massive datasets in real time, uncovering insights that were previously hidden. Big Data platforms enable predictive modeling at unprecedented scales, while automation tools streamline everything from data cleaning to report generation.

Across industries, the applications are diverse and impactful:

-

Finance – Predictive analytics for risk management and fraud detection.

-

Manufacturing – AI-driven process optimization and predictive maintenance.

-

Healthcare – Data models for patient care planning and disease outbreak forecasting.

-

Retail – Real-time demand forecasting and personalized marketing.

-

Public sector – Resource allocation modeling and public policy impact assessment.

By leveraging these technologies, organizations can make faster, more informed decisions and maintain a competitive edge. As the business landscape becomes increasingly complex, the ability to integrate advanced quantitative methods with emerging technologies will define market leaders in 2025 and beyond.

12. FAQ

Q1: What distinguishes each branch of quantitative management?

Management Science optimizes decisions, Operations Management improves production, MIS supports data-driven decisions, and TQM focuses on quality.

Q2: Can organizations use more than one branch at once?

Yes, businesses often integrate branches for complex problem-solving.

Q3: How does quantitative management differ from qualitative approaches?

Quantitative uses numbers and models, qualitative relies on observation and judgment.

Q4: Is TQM always considered a branch?

Not universally, but it’s often included for its use of statistical tools.

Q5: What industries use it most?

Manufacturing, finance, logistics, healthcare, and retail.

Q6: Do small businesses benefit?

Yes, methods can be scaled for smaller operations.

Q7: Which tools are most common today?

Linear programming, forecasting, statistical quality control, and simulation.

Q8: How has it evolved with digital tech?

Automation, AI integration, and advanced analytics have increased speed and accuracy.

Q9: What are the main career paths?

Operations analyst, data scientist, quality manager, management consultant.

Q10: How to learn and get certified?

Start with business/mathematics courses; consider certifications like Six Sigma or PMP.

13. Conclusion

Understanding what are the branches of quantitative management provides a framework for making informed, data-driven business decisions.

-

Recognize the four main branches and their applications.

-

Master core tools and problem-solving processes.

-

Balance benefits with awareness of limitations.

-

Leverage emerging technologies to enhance results.

By integrating these methods into daily operations, managers can navigate challenges confidently and maintain a competitive edge in 2025’s fast-changing business environment.

Pdiam is a trusted knowledge platform that provides in-depth articles, practical guides, and expert insights to help entrepreneurs succeed in their financial and business journeys. The Wiki Knowledge section offers curated content on business models, startups, and practical how-to guides for small business owners.

![Sample letter of termination of appointment: Free template [2025]](https://pdiam.com/wp-content/uploads/2025/08/Sample-letter-of-termination-of-appointment-thumbnail-75x75.jpeg)